Reverberatory Furnace

Reverberatory Furnaces for Aluminum Melting and Holding

Reverberatory furnaces are among the oldest and most widely used furnace types for melting and holding aluminum. Known for their versatility, they come in a broad range of sizes — from melting capacities of 1,000 to up to 40,000 lbs/hr and above (approximately 500–13,600 kg/h) to holding capacities ranging from 3,000 to 300,000 lbs (about 1,300–135,000 kg).

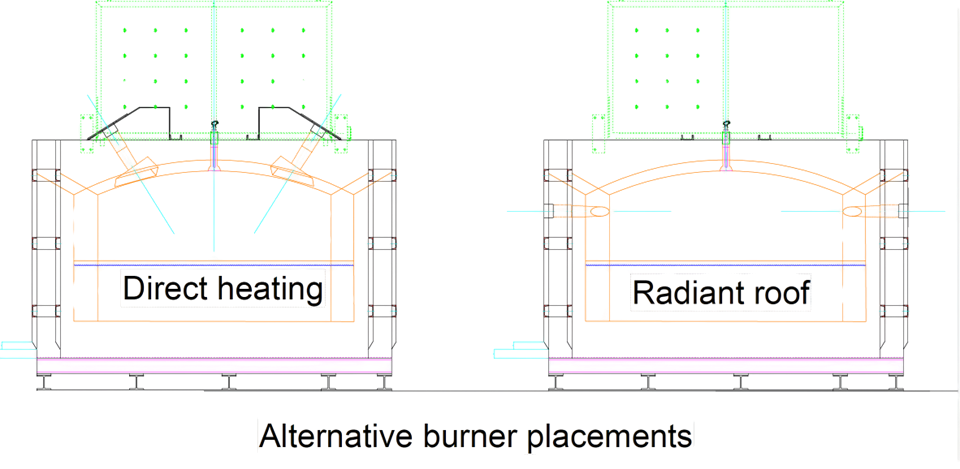

The term reverberatory refers to the reflection or reverberation of heat within the furnace. These furnaces isolate the molten metal from direct contact with the fuel, although the metal does interact with the hot combustion gases. Heat transfer occurs either by reflection from the furnace roof or through direct convection.

Furnace Configuration and Features

Melting can occur in two ways:

- On a dry hearth,

- Via direct immersion through a charge well,

Or a combination of both methods.

Transfer options include:

- Direct ladling pockets,

- Pump transfer systems,

- Integrated launders,

- Or tapping valves for ladle transfer.

In larger furnaces, bath circulation is essential for temperature uniformity and metal chemistry homogenity. This is typically achieved using:

- Pump systems circulating molten metal

- Impellor stirring systems (not so effective on larger baths

- Or underfloor electromagnetic stirrers.

Burners (gas or oil-fired) are mounted in the roof or side walls, depending on furnace size. In large systems, burners fire across the furnace to create a radiant roof heat zone, while in smaller furnaces, burners may be directed toward the bath.

Applications by Furnace Size

- Large reverberatory furnaces (50,000–300,000 lbs capacity) are typically found in primary and secondary aluminum cast houses, where metal homogeneity and certification are critical.

- Smaller reverberatory furnaces are ideal for aluminum casting operationssuch as die casting and sand casting, where they offer simplicity, flexibility, and reliable molten metal delivery.

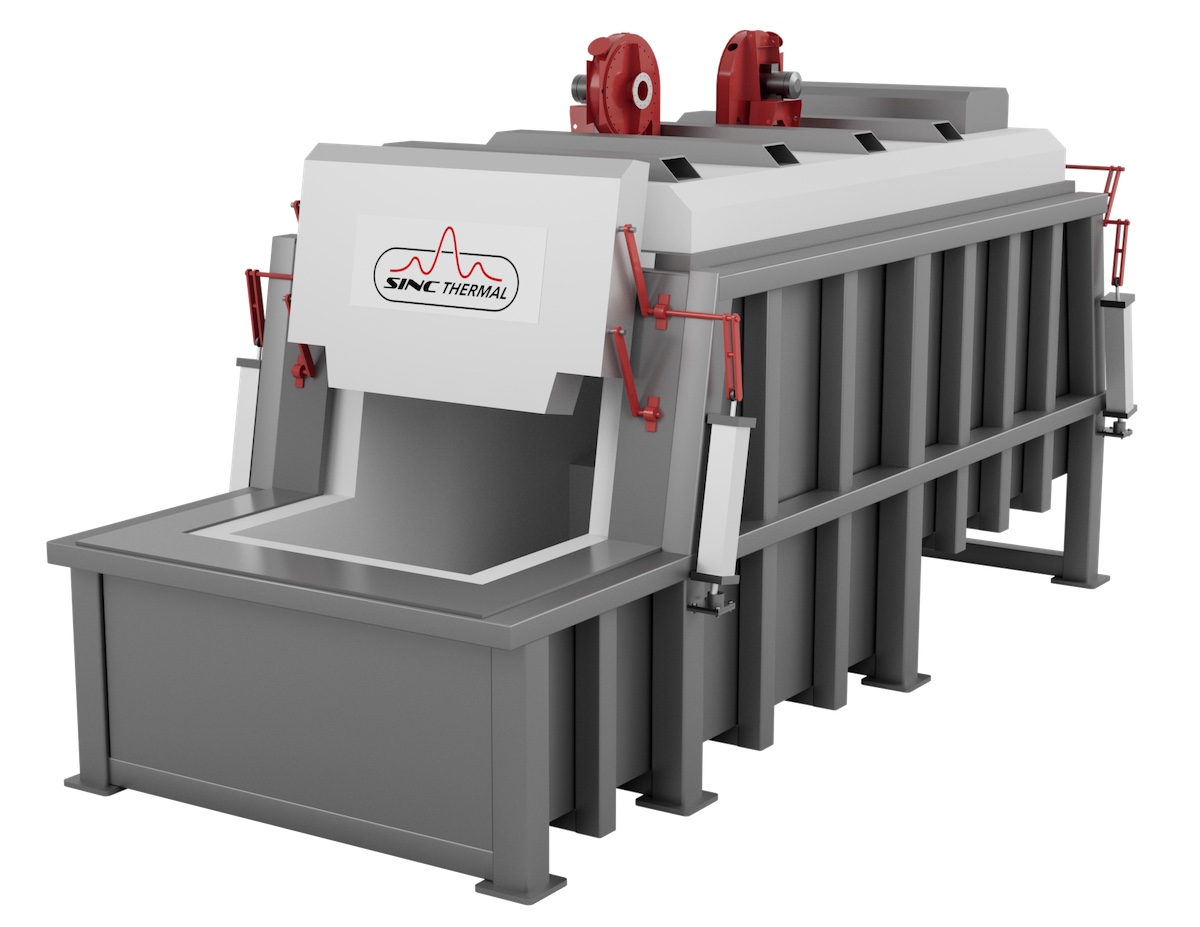

SINC Thermal’s Reverberatory Furnace Range

SINC Thermal offers a focused range of compact reverberatory furnaces tailored to the needs of aluminum casting facilities, with:

- Melting capacities from 1,000 to 4,000 lbs/hr (about 500–1,800 kg/hr),

- Holding capacities up to 12,000 lbs (around 5,500 kg).

Key Advantages:

- Compact footprint for limited floor space,

- Simple controls for ease of operation,

- Flexible charging (ingots or scrap) via fork truck or automated chargers,

- Cost-effective compared to shaft furnaces,

- Customizable features like:

- Bail-out or pump-out pockets,

- Tapping ports for direct ladle transfer,

- Built-in degassing via floor plugs or pocket-mounted lances,

- Dry hearth and large doors for full-stack ingot charging without damaging refractories.

While reverberatory furnaces have lower energy efficiency than shaft melting furnaces, this is offset by their operational simplicity, customizability, and lower capital cost — making them an excellent choice for aluminum foundries seeking productivity and flexibility.

Robust Construction

All SINC furnaces are designed and built with the same attention to detail and have a robust steel frame with carefully selected refractory insulation for maximum efficiency.

SINC’s reverberatory furnaces have a simpler optimized design for improved performance, efficiency and lower maintenance requirements, creating a perfect solution for local central melting in foundry applications.

Reverberatory furnaces offer a simple and robust means of melting and holding molten aluminum and can be configures in a variety of ways for direct charging into the molten metal in a charge well or independent melting on a dry hearth.

The absence of an efficient recuperative system for the charge material means they lack the overall energy efficiency of the shaft melting furnaces by up to 50%.

All SINC furnaces and equipment are proudly built in our facility in Missouri USA. Customers are always welcome to visit and monitor the build schedules of their furnaces and arrange for maintenance training sessions during the build process.

Furnace Advantages

- Simple robust construction.

- Simplicity of charging with fork truck devices.

- Suitable for large and/or low and high-density scrap charges.

- Larger bath capacities can be equipped with chip-melting submergence pump systems.

Additional Considerations

- The simplicity of a reverb inherently allows a high degree of flexibility to tackle challenging melt room applications with a wide range of options and configurations available.

- Ability to melt sows and T-bars to reduce feedstock costs.

- Reduced furnace efficiencies can sometimes be overcome by being able to accept a wider range of incoming materials. These include reduced pre-processing of scrap as well as the ability to accept sows, t-bars, full ingot stacks, and a variety of other feedstock.

- Automated charging equipment available by SINC Thermal.

SINC Thermal Headquarters